|

McCloud River Lumber Company:

Finished Products and Distribution |

|

|

|

|

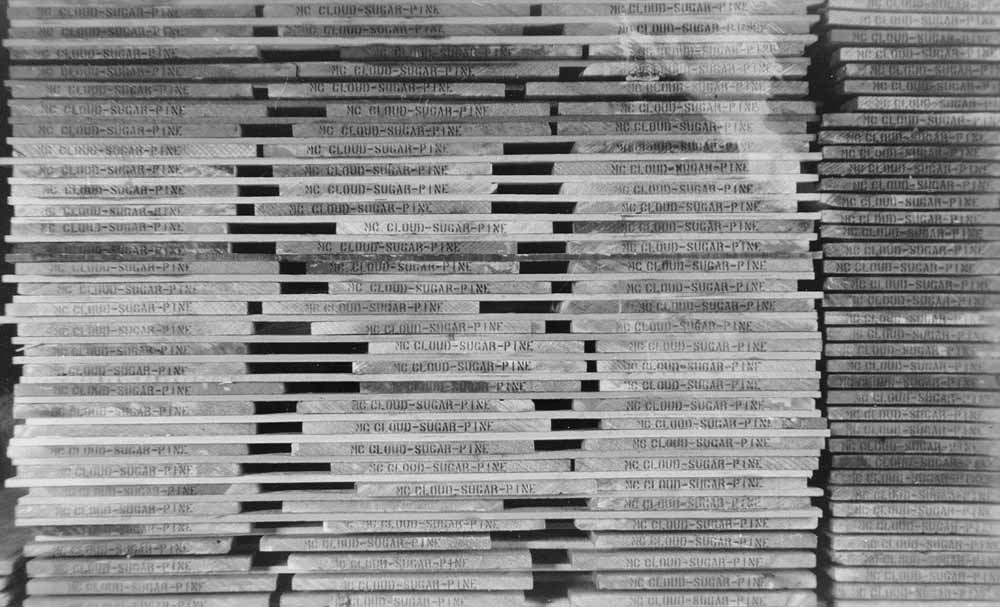

Sugar pine boards from the mill ready for shipment. Heritage Junction Museum. |

|

|

|

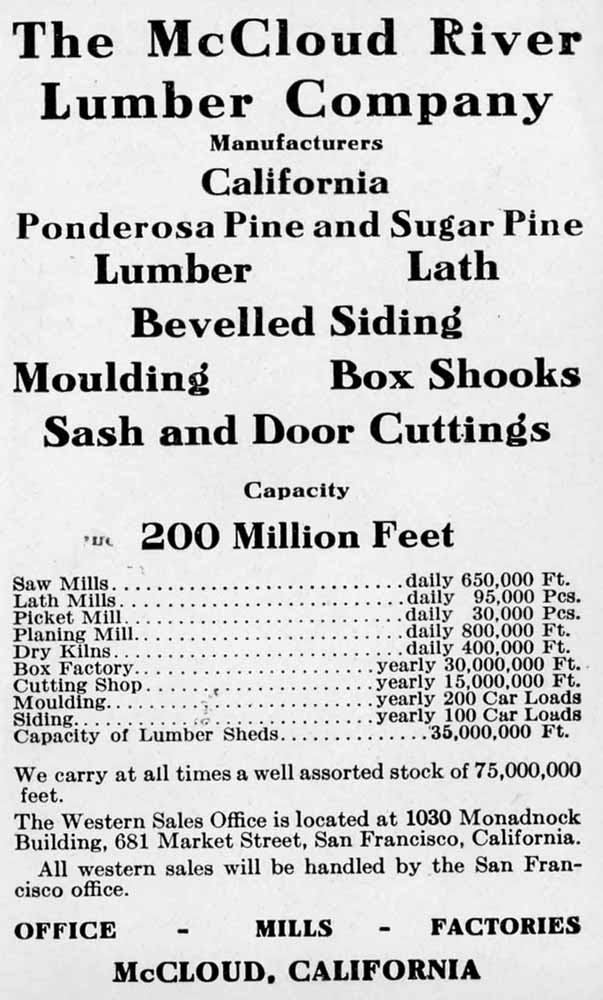

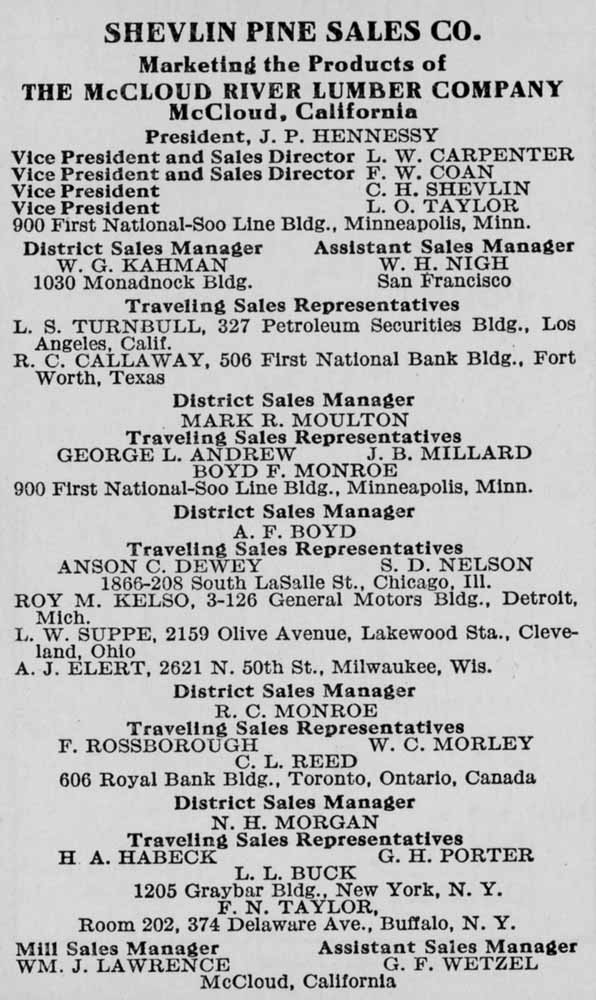

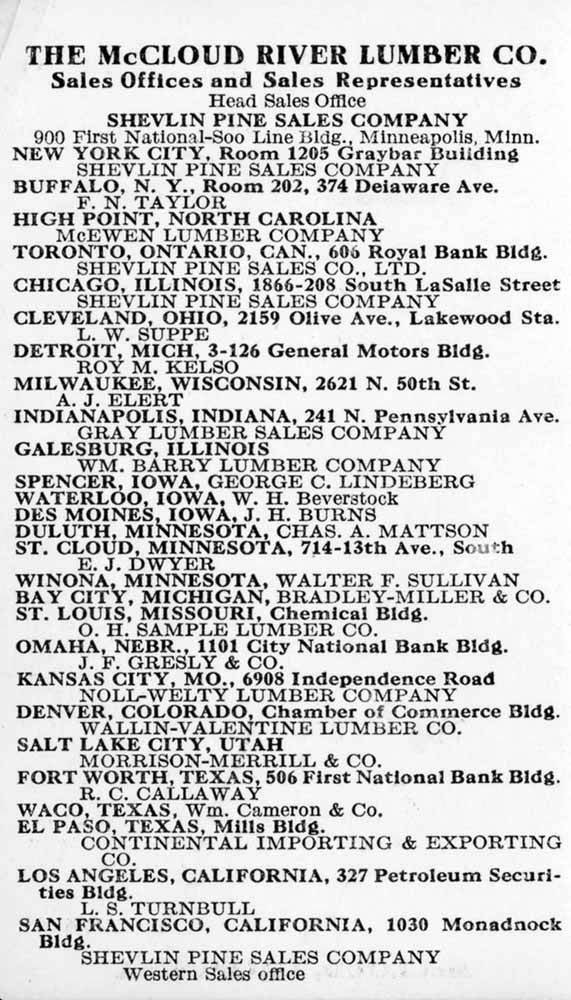

The McCloud River Lumber Company produced a wide variety of lumber products from the McCloud sawmills. The following pages are scanned from a 1932 pocket calendar that give details on the company, its officers, available products, sales and distribution networks, and freight rates. |

|

|

|

|

Introductory details. |

|

|

Company officers. |

|

|

The Shevlin Pine Sales distribution network and sales offices. |

|

|

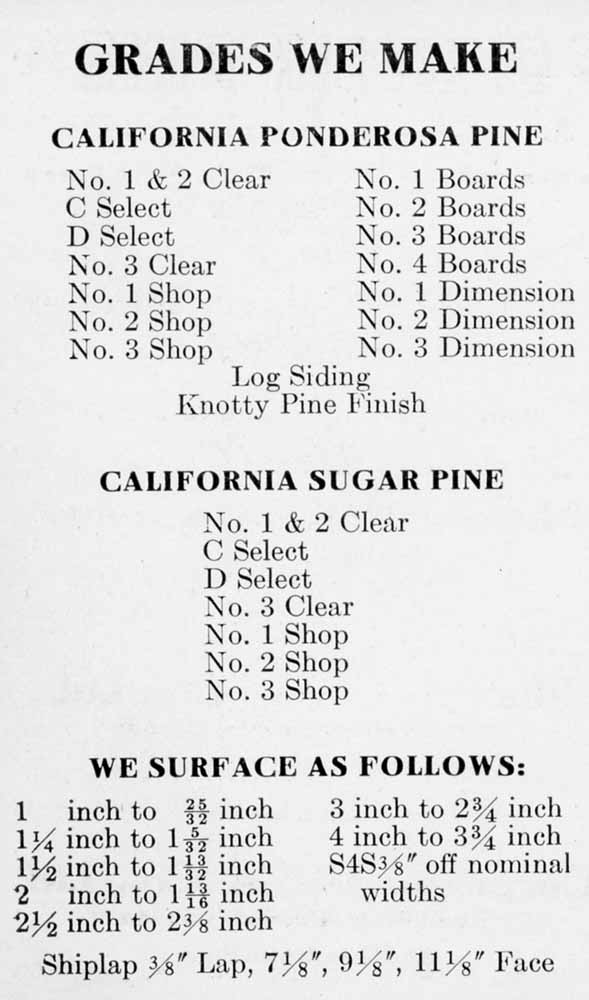

"Grades We Make". |

|

|

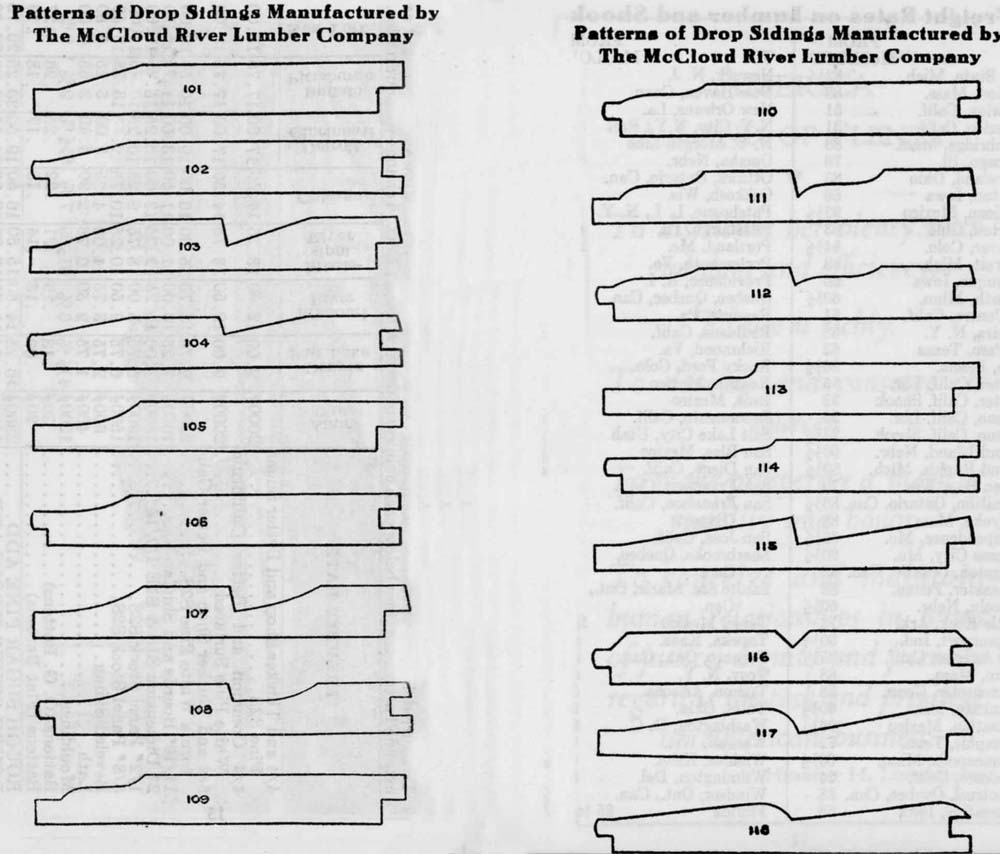

Drop Siding Patterns. |

|

|

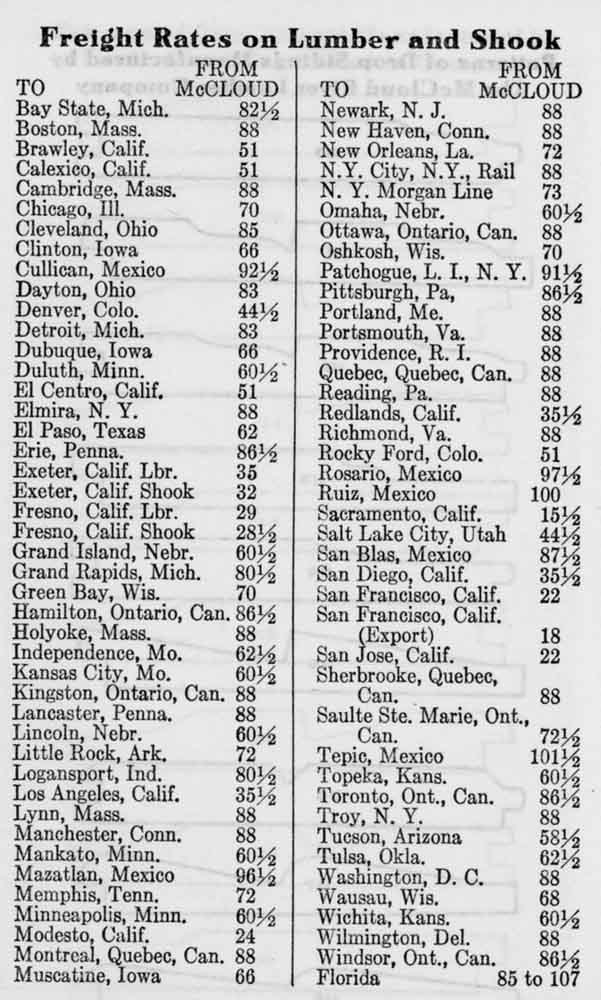

Lumber and Shook Freight Rates. |

|

|

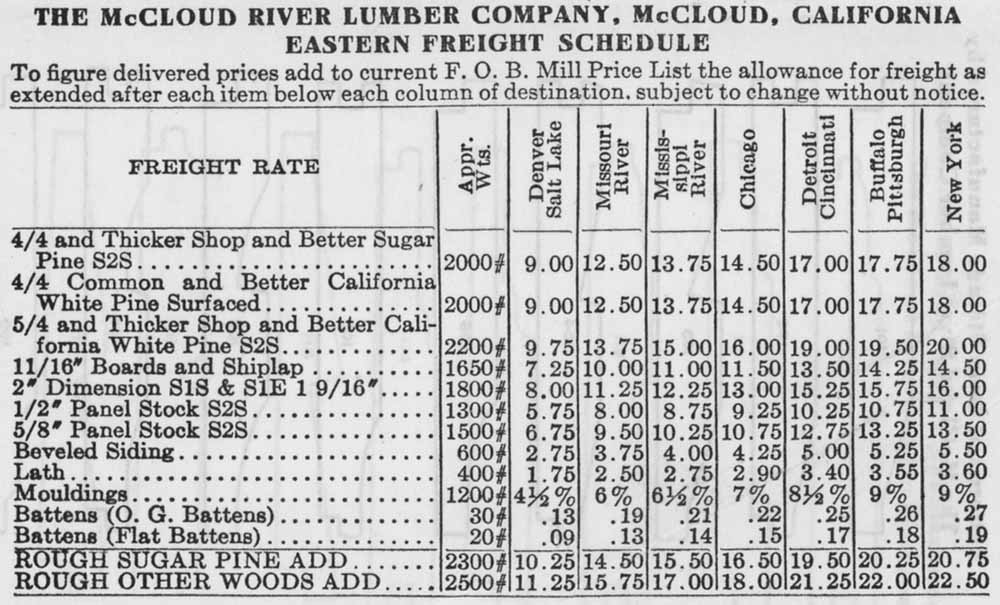

Eastern Freight Rate Schedule. |

|

|

|

One of the major and most often overlooked uses of pine through the first half of the 20th century was in wooden shipping boxes for the California citrus industry. Several things had to fall in place for this to happen, namely (1) the establshment of the vast California citrus and other agricultural product industry, (2) development of Eastern markets for the fresh produce, (3) perfection of the ice bunker wooden refrigerator car, and (4) establishing enough ice plants along the major east-west rail corridors to keep refrigerator cars cold during the journey east. All the pieces fell into place starting in the 1890s, and by the turn of the century there had developed a crushing demand for lumber, especially pine, to make wooden crates for shipping citrus and other fresh fruits and vegetables. The reliance citrus growers had upon the pine lumber industry caused many citrus growers to buy timberlands and sawmills so they could control their own box supply. Like almost every other sawmill in the region, the McCloud mill had a box factory adjacent to the mill, along with the other factories for things like sashes and doors. These box factories did not produce or ship finished boxes and crates but rather would cut all the pieces for a box, collectively referred to as box shook. All of the pieces for a box would be assembled into a bundle that would be wired together and then shipped to the packing shed, where the box would be assembled just prior to being filled with citrus. Some idea of the importance of the wooden box to the McCloud River operations can be gleaned from some statistics of the lumber company's 1917 operations. The two mills the company operated had a combined output of 97,778,471 board feet that year. McCloud's own box factory consumed a full thirty percent of that production, consuming 29,365,000 board feet of rough lumber to produced 27,232,000 of box shook. A full 1,048 of the 4,010.5 cars the lumber company shipped over the McCloud River Railroad that year were box shook loads, and 847 of the 2,500 lumber loads the lumber company shipped were to independent box factories in and around Sisson. The wood box remained an important use of pine and a major customer group for the industry into the middle 1950s, when the citrus growers and shippers transitioned to the cardboard shipping container almost overnight. |

|

|

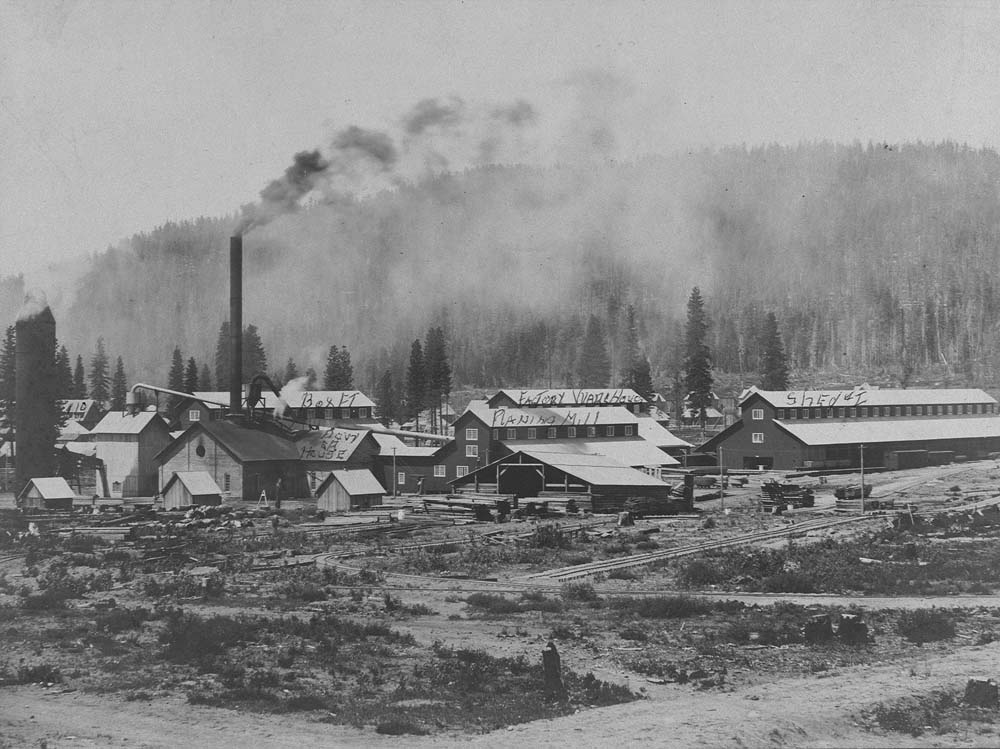

The box factory is labeled along with the other factories in this early picture of that part of the mill complex. Heritage Junction Museum. |

|

|

In this undated photo veteran McCloud River Railroad conductor "Chino" Haines is seen helping the box factory cut its final board. The event closed more than one circle, as Chino's father

had been on the first crew in the plant when it opened a half century or so before. Heritage Junction Museum. |

|

|

Assembled citrus boxes on display inside a restored ice bunker refrigerator car in the California State Railroad Museum in Sacramento, California. Sunkist was one of the fruit growing companies to

enter the northeastern California timber industry directly through their Fruit Growers Supply Company subsidiary, which at one time operated large sawmills in Hilt, Susanville, and Westwood, California. FGS

remains on the single largest private timberland owners in California today. |

|

|