|

McCloud River Railroads: Equipment

Lidgerwood and Clyde Skidders and Donkey Roster |

|

|

|

Clyde Four Line Skidder The Clyde Iron Works of Duluth, Minnesota, was an early and prolific manufacturer of specialized logging equipment. The company developed their double ended four-line skidder in the late 1800s or early 1900s, and it proved especially popular in the pine regions of the upper Midwest and Intermountain west. The McCloud River Lumber Company purchased one of these skidders in August 1907 for $8,500. The lumber company was apparently less than pleased with the machine, as it did not appear to have lasted long on the operations. |

|

|

The only known photo of McCloud's Clyde four line skidder. Heritage Junction Museum.

|

|

|

|

Lidgerwood Tower Skidder Logging came in many different forms and functions, depending on topography, available equipment, and operator preference. One of the constants in the industry is the need to transport logs from the stump to the landing, a central point to which logs would be brought for loading onto trains and then later trucks for the trip to the mill. The McCloud River Lumber Company used ground skidding and yarding systems through most of its history, in which animal, steam, and then internal combustion machines would drag logs across the ground. High lead logging systems on the other hand used elevated cables routed from a donkey engine through blocks on the top of a tower to drag logs partially on the ground or through the air into the landing. The "towers" normally employed in high lead systems were trees around the landing that were limbed, topped, and then rigged with guy wires and the hauling lines run out to anchor points scattered throughout the logging setting. In 1882 the Lidgerwood Manufacturing Company of Red Hook, Brooklyn, New York, added a tower skidder to their extensive line of construction and industrial equipment. Lidgerwood tower skidders carried their own steel towers built into the machines, which simplified their set up and operations. The company built the first of its skidders for Michigan loggers, and the technology spread to the west coast by 1904. All told a little more than one hundred Lidgerwood skidders would eventually be used on the west coast, most built by Puget Sound Iron & Steel Works in Tacoma, Washington, under license from Lidgerwood. Willamette Iron & Steel Works and Washingto Iron Works also built similar machines. The McCloud River Lumber Company purchased a new Lidgerwood skidder from Puget Sound Iron & Steel Works as part of investments made as it secured its future with the Bear Creek sale. Pacific Car & Foundry constructed the carrying car and shipped it to Puget Sound Iron & Steel on 1 February 1924. The McCloud machine was c/n 3012 and was equipped with a 12X14 engine and an 85-foot tall tower and rode on four trucks. Like most Lidgerwoods McCloud's model was equipped with both high and ground skidding lead capabilities, had a heal boom on one end that could load cars, and could be set up in the same manner as the McGiffert loaders with the frame open as a tunnel over tracks so that empty log cars could pass underneath the machine. McCloud put the machine to work upon its arrival and reserved the best stands of the trees for it. However, in 1926 a U.S. Forest Service employee monitoring the company's logging in the USFS Lava Beds sale noted the Lidgerwood produced fewer logs per man than the steam donkeys also in use; the Lidgerwood with a crew of 25 men had a maximum output of 125M (M being 1,000 board feet) per day, while the boom equipped steam donkeys with a crew of 18 men working in inferior timber stands yarded and loaded 75-80 M per day. The same employee also noted "The Lidgerwood skidder is the most destructive form of logging the McCloud Company has tried out. it is fully as bad as high lead logging. This machine has the advantage over the high lead, that it can be used with little damage to timber left standing if the crew will take the trouble necessary." The Lidgerwood remained in McCloud until 1934, though it's not certain how much use it saw after tractors replaced the steam machines in yarding in 1927-1928. McCloud sold the machine to Crown Willamette Paper Company (Washington Pulp & Paper Company), Neah Bay, Washington, who lengthened tower to 100 feet. Crown in turn sold it on 4 October 1946 to V.C. Monahan, d.b.a. Cabin Creek Lumber Company, for scrap. |

|

|

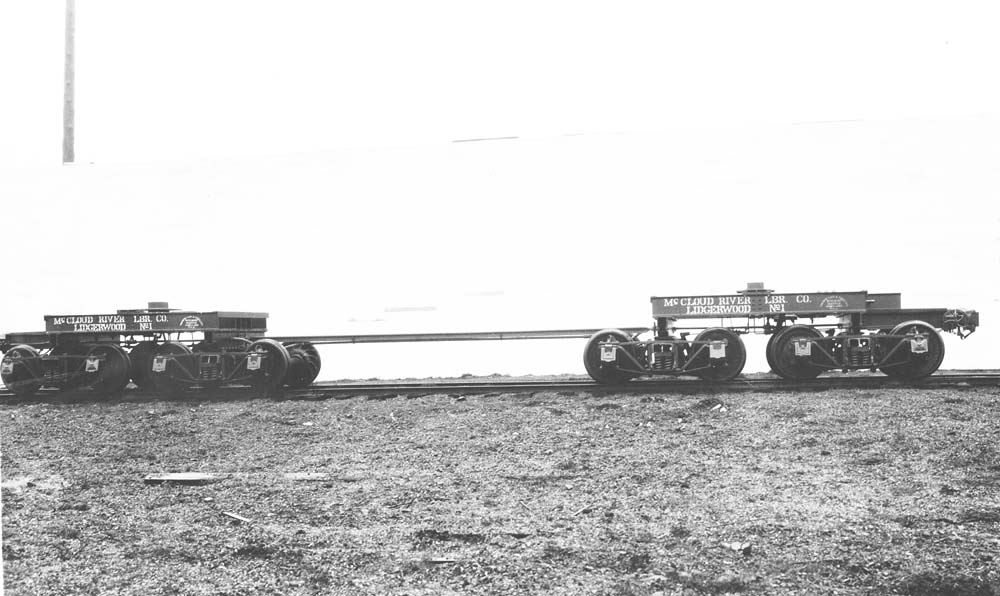

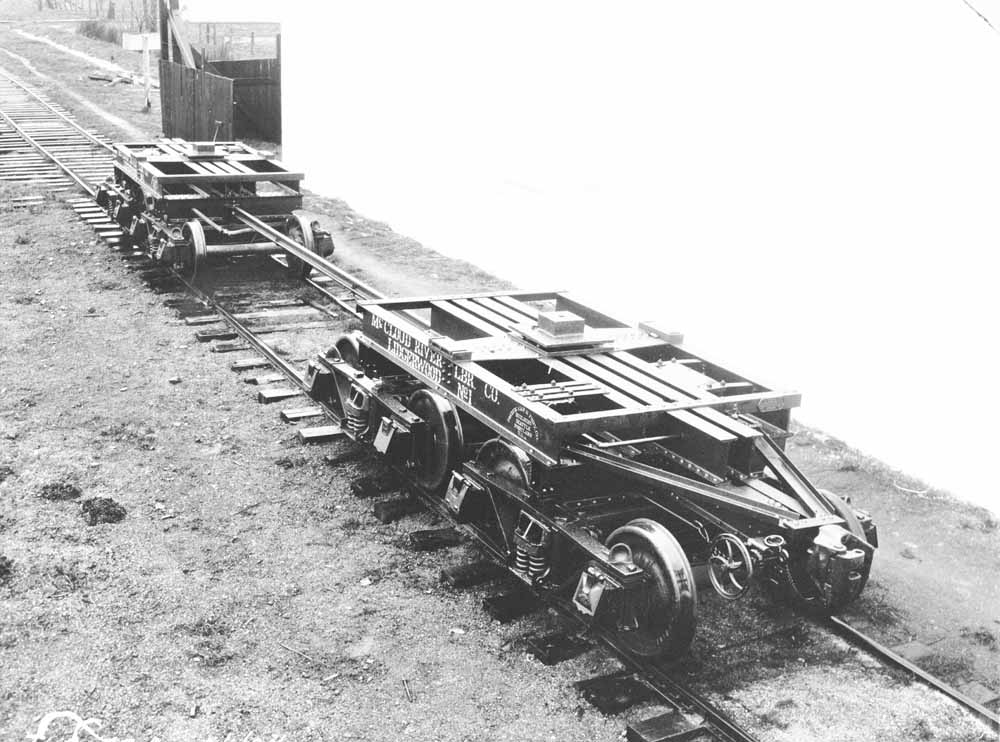

The carrying car at Pacific Car & Foundry immediately prior to its shipment to Puget Sound Iron & Steel Works. Pacific Northwest Virtual Logging Data Center.

|

|

|

A second view of the carrying car at the PC&F factory. Pacific Northwest Virtual Logging Data Center.

|

|

|

The Lidgerwood set up and working in 1926. Roland Edwards photo, courtesy Marilyn Rountree.

|

|

|

A partial side view of the Lidgerwood. Roland Edwards photo, courtesy Marilyn Rountree.

|

|

|

Another view of the Lidgerwood showing most of the tower. Roland Edwards photo, courtesy Marilyn Rountree.

|

|

|

One last view of the Lidgerwood at work. Hertige Junction Museum of McCloud, Inc.

|

|

|

|

Partial Steam Donkey Roster The McCloud River Lumber Company used many donkeys throughout the steam era. John Taubeneck has assembled the following partial roster of donkeys and other skidders used by the McCloud River, mostly from photographs, manufacturer records, and period trade publications. Washington Iron Works, Seattle, WA c/n 3532, 11x14+9x10-1/4, "yarder, 2 sp. + loader", blt. 3/24/1923 c/n 3688, 11x14+9x10-1/4, "yarder, 2 sp. + loader", blt. 3/13/1924 c/n 3688, 11x14+9x10-1/4, "yarder, 2 sp. + loader", blt. 3/13/1924. Purchased via Zimmerman-Wells-Brown Co. c/n 3689, 11x14+9x10-1/4, "yarder, 2 sp. + loader", blt. 3/22/1924. Purchased via Zimmerman-Wells-Brown Co. c/n 3805, 11x14+9x10-1/4, "yarder, 2 sp. + loader", blt. 3/1925. The above engines are unique machines built only for the McCloud River Lumber Co. They are a standard 2-speed yarder with an additional engine and single drum appended on the front of the frame. Builder's photos exist in the Sackman collection, Museum of History and Industry, Seattle, WA. xxxx, 11x16, "yarder, simple geared", blt. 3/1915. The 5/15/1915, issue of the WEST COAST LUMBERMAN, page 30, has a lengthy article on a new simple geared yarder by Washington Iron Works combining "the good qualities of the well known 'half breed' type and the compound geared yarder." An accompanying illustration shows one of the machines "recently shipped to the McCloud River Lumber Company, McCloud, California." The engine pictured has a guard over the connecting rods and valve rods "which gives protection on these reciprocating parts and removes the possibility of accident." No other owners are mentioned. xxxx, 11x11, compound geared yarder, blt. 4/1915. The 5/15/1915 issue of the WEST COAST LUMBERMAN lists this machines as a "recent sale." Willamette Iron & Steel Works, Portland, OR c/n 310, 10x13, Crack-a-Jack yarder, blt. 3/23/1907. c/n 311, 10x13, Crack-a-Jack yarder, blt. 2/12/1907. c/n 548, 10x13, Humboldt yarder, blt. 2/1/1910. Built for McCloud River Lumber Co.; sold 6/17/1925 to Zimmerman-Wells-Brown (Dealer); sold 1934 to Berlin Log Co., Lake Stevens, WA; sold 1936 to H. & L. Lumber Co., Junction City, OR. c/n 557, 10x13, Humboldt yarder, blt. 02-16-10. Built for McCloud River Lumber Co.; sold to Zimmerman-Wells-Brown (Dealer); sold 7/15/1925 to Pioneer Lumber Co., Curtis, OR. c/n 558, 10x13, Humboldt yarder, blt. 2/04/1910. c/n 559, 10x13, Humboldt yarder, blt. 2/25/1910. c/n 597, 10x13, Crack-a-Jack yarder, blt. 4/22/1909. c/n 694, 10x13, Humboldt yarder, blt. 3/31/1910. c/n 1498, 11x13, Humboldt yarder, blt. 2/8/1918. Built for McCloud River Lumber Co.; sold to C. F. Ruggles, Martel, CA; sold 1/31/1926 to Northern Redwood Lumber Co., Korbel, CA; sold 11/28/1926 to Dolly Varden Lumber Co., Arcata, CA. c/n 1939, 11x13, Humboldt yarder, blt. 2/24/1923. c/n 1981, 11x13, Humboldt yarder, blt. 7/19/1922. c/n 1982, 11x13, Humboldt yarder, blt. 7/1/1922. McCloud purchased an auxiliary loader with 8x8 cylinders for engine #1982 in 12/1923 (shipped 1/3/1924). Willamette records give no construction number for the loader, but it is noted as Type MLSTF G-1 on the engine record for engine #1982 which also notes it as "built by Hess Erstad Iron Works." McCloud transferred this engine from #1982 to #1981 between January and March of 1925. Other Manufacturers - vertical spool Dolbeer, possibly Murray Brothers Machine Works. - Marshutz & Cantrell or Moore & Scott “Bull Donkey” (roader) - Washington roader, circa 1913-1916. McCloud essentially ceased using donkey engines after the first tractors arrived in the middle 1920s. Some of the donkeys may have been sold for further use in the Philippine Islands. |

|

|